Some Known Facts About Dust Extractors For Small Workshops.

The Ultimate Guide To Dust Extractors For Small Workshops

Table of ContentsA Biased View of Dust Extractors For Small Workshops9 Easy Facts About Dust Extractors For Small Workshops ShownHow Dust Extractors For Small Workshops can Save You Time, Stress, and Money.Rumored Buzz on Dust Extractors For Small Workshops

The challenges for foundry dirt collection systems rotate around crystalline silica dirt, carbon monoxide, and warmth, which are poisonous combinations. These factors make meeting air high quality criteria challenging as well as demanding. Therefore, when selecting a dirt control system for a foundry, the initial factor to consider is the capacity of the system to stand up to rough as well as dangerous work environment problems.

Dust collection systems for this kind of operation should be especially made to fit the type of layer being applied. The objective of the system is to manage and minimize overspray and also dirt.

It would seem likely to increase airflow as well as movement, this kind of service may be inefficient as well as waste power. The design of the cubicle depends on the pressure of the air entering the cell or cubicle. For many systems, it is very important to have a mild vacuum cleaner in the booth to stay clear of possible positive stress.

Not known Factual Statements About Dust Extractors For Small Workshops

Another method is simply putting the makeup air link on the top of the cubicle. Despite the design, it is crucial for the cleaning of the air to have cross ventilation. Similar to a cleanroom, air flow in a thermal spray booth can be either straight or downward, though the down layout is best for dirt collection systems.

The pharmaceutical sector is a highly regulated sector with comprehensive and specific regulations. Dust from pharmaceuticals is generated primarily during the manufacturing and also packaging of items. Each step of creating a medication, which includes granulating, drying out, mixing, pressing, finish, as well as grinding, generates large quantities of dirt that require to be gotten rid of.

Intercepting and controlling this dissemination is the function of the dust control system. When developing a dust control system for a pharmaceutical plant, the first consideration is mapping the air flow system to track the path of dirt, fumes, existing air movement patterns, and also feasible evolutionary changes. Since lots of pharmaceutical dirts are flammable, the layout of the air flow system is incredibly important.

HEPA filters are typically discovered in pharmaceutical dust control systems since they are the most efficient as well as dependable. Similar to a foundry system, they are installed as discover this an additional defense to achieve zero discharges. Reusing generates a good deal of dirt as an all-natural end result of reducing items to their resources.

The Buzz on Dust Extractors For Small Workshops

Dust comes from after materials are shredded, crushed, or have paint or lacquer eliminated. All recycling centers are required to abide by air top quality standards. As they function to meet top quality criteria as well as control pollutants, they have actually identified that dust control is a significant issue, leading to the large use dirt collection systems to alleviate as well as include the issue. dust extractors Visit This Link for small workshops.

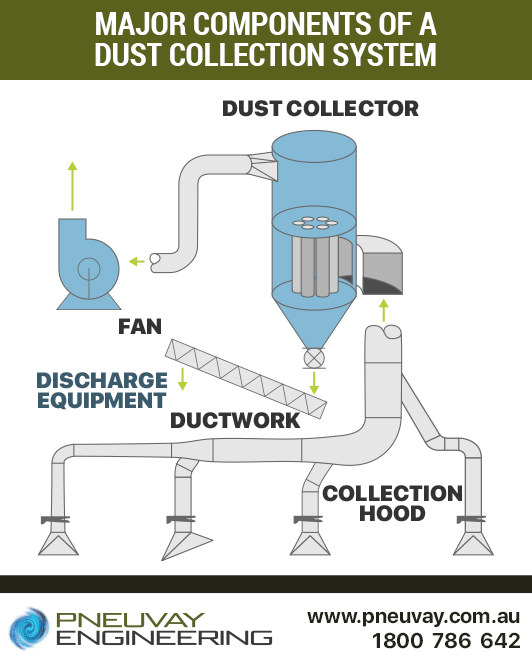

When manufacturers pick a dust control system, they are recommended by manufacturers about the type of system that would certainly best fit their requirements since purchasing as well as mounting a dirt control system is a major financial investment. Particle matter comes in a wide range of kinds, from silicon dirt to timber chips and also sawdust.

The Buzz on Dust Extractors For Small Workshops

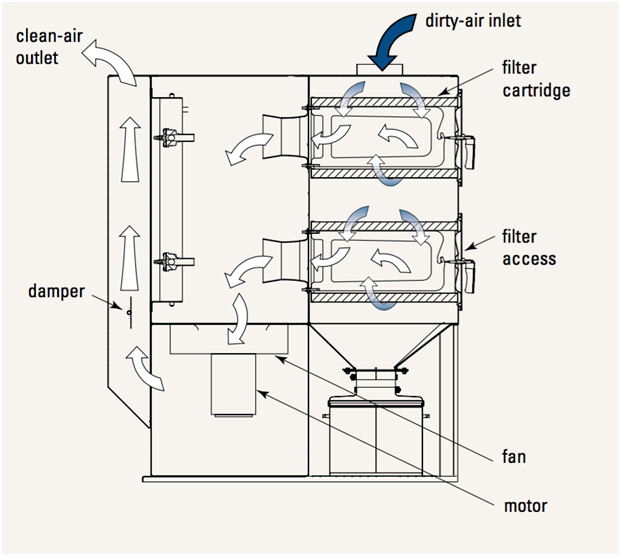

Textile filter bags in a cartridge system are the most efficient method for collecting dust. Dirt collection systems are covered to have the dirt as well as clean the air.

Plastic Dust High-Density Polyethylene (HDPE) dust is generated in the manufacturing of plastic panels when they are designed and also developed on an edge leaner, grinder, or miter saw. Paper Dirt One of the more common kinds of dirt is paper dust, the negative effects of the manufacturing of numerous kinds of paper.

With the intro of dirt collection systems, employees are safer as well as much more safeguarded. Sugar Sugar dust is the byproduct of the production of candy. Pulse jet systems are made use of to maintain the filters of the dust collection system particulate-free. The accumulated material is eliminated as well as collected in drums. Zinc Zinc dust is generated in the blog galvanizing process.

Rice Dust Rice dirt has extremely fine and minute bits that accumulate throughout the production of rice-based products. A dirt collection system is required for the security as well as security of employees.